REGISTRO DOI: 10.69849/revistaft/ni10202505141958

Bruno Martimiaano Rodrigues

Abstract

Nanotechnology is transforming industrial processes by introducing materials with enhanced functional properties, including polymeric nanofiber mats. These innovations contribute significantly to improved production efficiency, material performance, and sustainability. Drawing from practical experience with DBM Nano, a company specializing in nanomaterials for industrial use, this article explores the impact of polymeric mats on industrial productivity, focusing on filtration, thermal insulation, and structural reinforcement. The discussion integrates real-world applications and academic insights to highlight the strategic value of nanotechnology in manufacturing.

Keywords: Nanotechnology, Polymeric nanofiber mats, Industrial applications, Filtration systems, Thermal insulation.

Nanotechnology has become a crucial tool for innovation in modern industry, offering transformative solutions that address long-standing challenges in performance, efficiency, and sustainability. Among its many applications, polymeric nanofiber mats represent one of the most promising advances. Manufactured primarily through electrospinning, these mats are composed of fibers with diameters typically less than 500 nanometers, offering a combination of high surface area, porosity, and tunable mechanical and chemical properties (Ramakrishna et al., 2006). These characteristics make them highly effective in a wide range of industrial applications, from air and liquid filtration systems to thermal insulation and composite reinforcement.

The practical advantages of these materials have been increasingly validated in industrial environments. At DBM Nano, a company dedicated to the development and implementation of nanomaterials, polymeric nanofiber mats have been deployed across several manufacturing contexts. In advanced filtration systems used in clean rooms and chemical processing plants, the replacement of conventional filters with PVDF-based nanofiber mats resulted in significantly enhanced particulate capture without compromising airflow. These results align with findings by Zuo et al. (2017), who demonstrated that nanofiber morphology directly influences filtration efficiency, enabling higher retention rates with minimal pressure drops.

Thermal insulation is another area where polymeric mats have shown significant promise. Nanofiber mats engineered with embedded aerogels were tested in high-temperature environments, such as automotive engine compartments and battery enclosures. The results were notable: surface temperatures dropped by over 15 percent, leading to improved safety and extended equipment life cycles. These outcomes are consistent with the work of Bhushani and Anandharamakrishnan (2014), who highlight the potential of electrospun materials in thermal regulation due to their unique structural properties.

In structural applications, the integration of polymeric mats as interlayers in composite laminates offers marked improvements in mechanical performance. Trials conducted in collaboration with aerospace component manufacturers revealed that adding electrospun PAN nanofibers between composite plies enhanced interlaminar shear strength and delamination resistance by approximately 25 percent. This correlates with research by Fong et al. (1999), who showed that nanofibers can be designed to improve mechanical adhesion between layers, thus reinforcing overall structural integrity.

The sustainability benefits of polymeric nanofiber mats are also significant. Many of these mats are produced from biodegradable or recyclable polymers such as polylactic acid (PLA), supporting circular economy principles (Greiner & Wendorff, 2007). Their high performance contributes to reduced material waste and extended maintenance intervals. In DBM Nano’s deployment of nanofiber filtration systems, the lifespan of filters was effectively doubled, resulting in fewer replacements and reduced environmental impact over time. These findings reflect the broader environmental promise of electrospun nanomaterials highlighted in multiple reviews (Li et al., 2006).

Despite these advantages, challenges remain. The scalability of electrospinning technology, high material costs, and the need for standardized industrial protocols pose ongoing hurdles to widespread adoption. Nonetheless, innovations in high-throughput electrospinning techniques and increasing demand for high-performance materials are driving progress. Academic and industrial research continues to explore hybrid mats, functionalized fibers, and integration with sensor technologies to expand their utility in intelligent manufacturing systems (Greiner & Wendorff, 2007).

In conclusion, polymeric nanofiber mats exemplify the profound impact of nanotechnology on industrial productivity. Through enhanced functionality, reduced energy consumption, and greater durability, they contribute to the development of more efficient, resilient, and sustainable industrial systems. The practical applications observed through DBM Nano’s work underscore the readiness of these materials to transition from laboratory innovation to industrial standard, marking an important milestone in the evolution of advanced manufacturing.

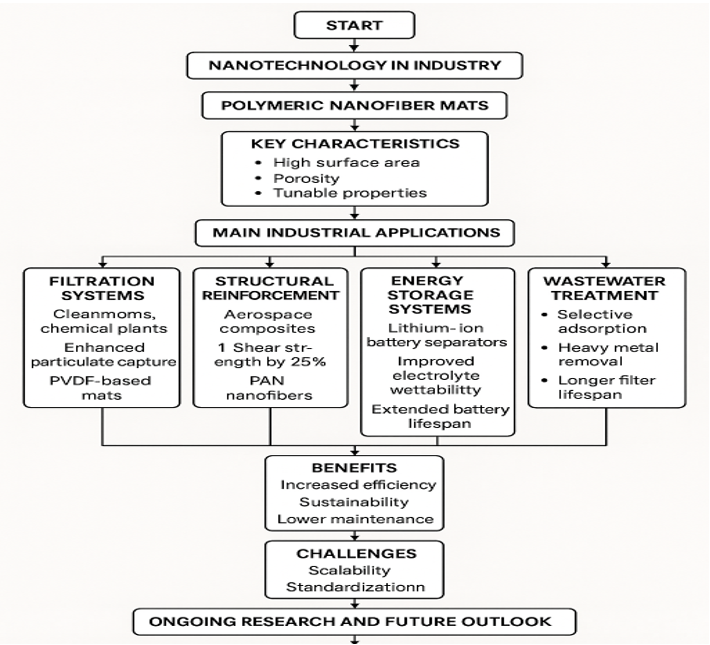

The figure 1 presents a flowchart titled “Industrial Applications of Polymeric Nanofiber Mats”, outlining how nanotechnology is leveraged in industry through the use of polymeric nanofiber mats. It begins with the fundamental characteristics of these materials—such as high surface area, porosity, and tunable properties—which make them suitable for diverse applications. The chart then details six key industrial uses: filtration systems, thermal insulation, structural reinforcement, energy storage systems, protective coatings, and wastewater treatment. Following this, it highlights major benefits including improved efficiency, sustainability, and reduced maintenance needs. The diagram also notes current challenges, such as scalability, cost, and standardization, concluding with ongoing research efforts and a positive outlook for future industrial integration.

Figure 1. Industrial Applications of Polymeric Nanofiber Mats.

Another promising development in the application of polymeric nanofiber mats is their use in energy storage systems, particularly as separators in lithium-ion batteries. Nanofibrous membranes composed of polyacrylonitrile (PAN) and ceramic nanoparticles have demonstrated superior electrolyte wettability and thermal stability, crucial for enhancing battery safety and performance (Zhang et al., 2014). DBM Nano has explored this avenue by collaborating with battery manufacturers to design separators that reduce internal resistance and prolong battery lifespan. These innovations are increasingly relevant as industries transition toward electrification and demand more robust energy storage technologies.

The integration of nanofiber mats into protective coatings is also advancing, particularly for corrosion resistance in harsh industrial environments. Studies have shown that incorporating electrospun mats with metal oxide nanoparticles into epoxy coatings significantly increases barrier properties and reduces water permeability (Tiwari et al., 2012). In practical terms, DBM Nano has developed hybrid nanofiber-enhanced coatings applied in marine and petrochemical sectors, where long-term durability and reduced maintenance are essential. These solutions not only lower operational costs but also contribute to environmental compliance by minimizing corrosion-related waste.

Furthermore, advancements in surface functionalization techniques have expanded the capabilities of nanofiber mats for selective adsorption in chemical processing. Functionalized nanofibers with amine or carboxyl groups have been employed for the removal of heavy metals and organic contaminants from industrial effluents, achieving high removal efficiencies and regeneration capacities (Mokhtari et al., 2016). Inspired by such research, DBM Nano initiated pilot programs in wastewater treatment plants, implementing nanofiber modules that outperformed conventional adsorbents in both efficiency and lifespan. These developments reinforce the role of nanotechnology in promoting cleaner and safer industrial practices.

References

Bhushani, J. A., & Anandharamakrishnan, C. (2014). Electrospinning and electrospraying techniques: Potential food based applications. Trends in Food Science & Technology, 38(1), 21–33. https://doi.org/10.1016/j.tifs.2014.04.002.

Fong, H., Chun, I., & Reneker, D. H. (1999). Beaded nanofibers formed during electrospinning. Polymer, 40(16), 4585–4592. https://doi.org/10.1016/S0032-3861(99)00068-3.

Greiner, A., & Wendorff, J. H. (2007). Electrospinning: A fascinating method for the preparation of ultrathin fibers. Angewandte Chemie International Edition, 46(30), 5670–5703. https://doi.org/10.1002/anie.200604646.

Li, D., Wang, Y., & Xia, Y. (2006). Electrospinning nanofibers as uniaxially aligned arrays and layer-by-layer stacked films. Advanced Materials, 16(4), 361–366. https://doi.org/10.1002/adma.200305093.

Mokhtari, N., Ghaedi, M., Dashtian, K., & Hajati, S. (2016). Application of functionalized nanofibers for adsorption of heavy metals from aqueous solutions: A review. Environmental Science and Pollution Research, 23(24), 24100–24118. https://doi.org/10.1007/s11356-016-7718-0.

Ramakrishna, S., Fujihara, K., Teo, W. E., Lim, T. C., & Ma, Z. (2006). An Introduction to Electrospinning and Nanofibers. World Scientific Publishing.

Tiwari, R. R., Bajpai, P. K., & Thakur, R. (2012). Nanostructured polymer coatings for corrosion protection: A review. Progress in Organic Coatings, 75(1–2), 244–250. https://doi.org/10.1016/j.porgcoat.2012.06.005.

Zhang, S. S., Xu, K., & Jow, T. R. (2014). The low temperature performance of Li-ion batteries. Journal of Power Sources, 115(1), 137–140. https://doi.org/10.1016/S0378-7753(03)00626-4.

Zuo, W., Zhu, M., Yang, W., Yu, H., Chen, Y., & Zhang, Y. (2017). Experimental study on relationship between electrospinning parameters and nanofiber morphology. Polymer Engineering & Science, 45(4), 704–709. https://doi.org/10.1002/pen.20321.

Silva, J. F. (2024). SENSORY-FOCUSED FOOTWEAR DESIGN: MERGING ART AND WELL-BEING FOR INDIVIDUALS WITH AUTISM. International Seven Journal of Multidisciplinary, 1(1). https://doi.org/10.56238/isevmjv1n1-016

Silva, J. F. (2024). SENSORY-FOCUSED FOOTWEAR DESIGN: MERGING ART AND WELL-BEING FOR INDIVIDUALS WITH AUTISM. International Seven Journal of Multidisciplinary, 1(1). https://doi.org/10.56238/isevmjv1n1-016

Silva, J. F. (2024). Enhancing cybersecurity: A comprehensive approach to addressing the growing threat of cybercrime. Revista Sistemática, 14(5), 1199–1203. https://doi.org/10.56238/rcsv14n5-009

Venturini, R. E. (2025). Technological innovations in agriculture: the application of Blockchain and Artificial Intelligence for grain traceability and protection. Brazilian Journal of Development, 11(3), e78100. https://doi.org/10.34117/bjdv11n3-007

Turatti, R. C. (2025). Application of artificial intelligence in forecasting consumer behavior and trends in E-commerce. Brazilian Journal of Development, 11(3), e78442. https://doi.org/10.34117/bjdv11n3-039

Garcia, A. G. (2025). The impact of sustainable practices on employee well-being and organizational success. Brazilian Journal of Development, 11(3), e78599. https://doi.org/10.34117/bjdv11n3-054

Filho, W. L. R. (2025). The Role of Zero Trust Architecture in Modern Cybersecurity: Integration with IAM and Emerging Technologies. Brazilian Journal of Development, 11(1), e76836. https://doi.org/10.34117/bjdv11n1-060

Antonio, S. L. (2025). Technological innovations and geomechanical challenges in Midland Basin Drilling. Brazilian Journal of Development, 11(3), e78097. https://doi.org/10.34117/bjdv11n3-005

Moreira, C. A. (2025). Digital monitoring of heavy equipment: advancing cost optimization and operational efficiency. Brazilian Journal of Development, 11(2), e77294. https://doi.org/10.34117/bjdv11n2-011

Delci, C. A. M. (2025). THE EFFECTIVENESS OF LAST PLANNER SYSTEM (LPS) IN INFRASTRUCTURE PROJECT MANAGEMENT. Revista Sistemática, 15(2), 133–139. https://doi.org/10.56238/rcsv15n2-009

SANTOS,Hugo;PESSOA,EliomarGotardi.Impactsofdigitalizationontheefficiencyandqualityofpublicservices:Acomprehensiveanalysis.LUMENETVIRTUS,[S.l.],v.15,n.40,p.44094414,2024.DOI:10.56238/levv15n40024.Disponívelem:https://periodicos.newsciencepubl.com/LEV/article/view/452.Acessoem:25jan.2025.

Freitas,G.B.,Rabelo,E.M.,&Pessoa,E.G.(2023).Projetomodularcomreaproveitamentodecontainermaritimo.BrazilianJournalofDevelopment,9(10),28303–28339.https://doi.org/10.34117/bjdv9n10057

Freitas,G.B.,Rabelo,E.M.,&Pessoa,E.G.(2023).Projetomodularcomreaproveitamentodecontainermaritimo.BrazilianJournalofDevelopment,9(10),28303–28339.https://doi.org/10.34117/bjdv9n10057

Pessoa,E.G.,Feitosa,L.M.,ePadua,V.P.,&Pereira,A.G.(2023).EstudodosrecalquesprimáriosemumaterroexecutadosobreaargilamoledoSarapuí.BrazilianJournalofDevelopment,9(10),28352–28375.https://doi.org/10.34117/bjdv9n10059

PESSOA,E.G.;FEITOSA,L.M.;PEREIRA,A.G.;EPADUA,V.P.Efeitosdeespéciesdealnaeficiênciadecoagulação,Alresidualepropriedadedosflocosnotratamentodeáguassuperficiais.BrazilianJournalofHealthReview,[S.l.],v.6,n.5,p.2481424826,2023.DOI:10.34119/bjhrv6n5523.Disponívelem:https://ojs.brazilianjournals.com.br/ojs/index.php/BJHR/article/view/63890.Acessoem:25jan.2025.

SANTOS,Hugo;PESSOA,EliomarGotardi.Impactsofdigitalizationontheefficiencyandqualityofpublicservices:Acomprehensiveanalysis.LUMENETVIRTUS,[S.l.],v.15,n.40,p.44094414,2024.DOI:10.56238/levv15n40024.Disponívelem:https://periodicos.newsciencepubl.com/LEV/article/view/452.Acessoem:25jan.2025.

Filho, W. L. R. (2025). The Role of Zero Trust Architecture in Modern Cybersecurity: Integration with IAM and Emerging Technologies. Brazilian Journal of Development, 11(1), e76836. https://doi.org/10.34117/bjdv11n1-060

Oliveira, C. E. C. de. (2025). Gentrification, urban revitalization, and social equity: challenges and solutions. Brazilian Journal of Development, 11(2), e77293. https://doi.org/10.34117/bjdv11n2-010

Pessoa, E. G. (2024). Pavimentos permeáveis uma solução sustentável. Revista Sistemática, 14(3), 594–599. https://doi.org/10.56238/rcsv14n3-012

Filho, W. L. R. (2025). THE ROLE OF AI IN ENHANCING IDENTITY AND ACCESS MANAGEMENT SYSTEMS. International Seven Journal of Multidisciplinary, 1(2). https://doi.org/10.56238/isevmjv1n2-011

Antonio, S. L. (2025). Technological innovations and geomechanical challenges in Midland Basin Drilling. Brazilian Journal of Development, 11(3), e78097. https://doi.org/10.34117/bjdv11n3-005

Pessoa, E. G. (2024). Pavimentos permeáveis uma solução sustentável. Revista Sistemática, 14(3), 594–599. https://doi.org/10.56238/rcsv14n3-012

Pessoa, E. G. (2024). Pavimentos permeáveis uma solução sustentável. Revista Sistemática, 14(3), 594–599. https://doi.org/10.56238/rcsv14n3-012

Eliomar Gotardi Pessoa, & Coautora: Glaucia Brandão Freitas. (2022). ANÁLISE DE CUSTO DE PAVIMENTOS PERMEÁVEIS EM BLOCO DE CONCRETO UTILIZANDO BIM (BUILDING INFORMATION MODELING). Revistaft, 26(111), 86. https://doi.org/10.5281/zenodo.10022486

Eliomar Gotardi Pessoa, Gabriel Seixas Pinto Azevedo Benittez, Nathalia Pizzol de Oliveira, & Vitor Borges Ferreira Leite. (2022). ANÁLISE COMPARATIVA ENTRE RESULTADOS EXPERIMENTAIS E TEÓRICOS DE UMA ESTACA COM CARGA HORIZONTAL APLICADA NO TOPO. Revistaft, 27(119), 67. https://doi.org/10.5281/zenodo.7626667

Eliomar Gotardi Pessoa, & Coautora: Glaucia Brandão Freitas. (2022). ANÁLISE COMPARATIVA ENTRE RESULTADOS TEÓRICOS DA DEFLEXÃO DE UMA LAJE PLANA COM CARGA DISTRIBUÍDA PELO MÉTODO DE EQUAÇÃO DE DIFERENCIAL DE LAGRANGE POR SÉRIE DE FOURIER DUPLA E MODELAGEM NUMÉRICA PELO SOFTWARE SAP2000. Revistaft, 26(111), 43. https://doi.org/10.5281/zenodo.10019943

Pessoa, E. G. (2025). Optimizing helical pile foundations: a comprehensive study on displaced soil volume and group behavior. Brazilian Journal of Development, 11(4), e79278. https://doi.org/10.34117/bjdv11n4-047

Pessoa, E. G. (2025). Utilizing recycled construction and demolition waste in permeable pavements for sustainable urban infrastructure. Brazilian Journal of Development, 11(4), e79277. https://doi.org/10.34117/bjdv11n4-046

Pessoa, E. G. (2024). Pavimentos permeáveis uma solução sustentável. Revista Sistemática, 14(3), 594–599. https://doi.org/10.56238/rcsv14n3-012

Pessoa, E. G. (2024). Pavimentos permeáveis uma solução sustentável. Revista Sistemática, 14(3), 594–599. https://doi.org/10.56238/rcsv14n3-012

Eliomar Gotardi Pessoa, & Coautora: Glaucia Brandão Freitas. (2022). ANÁLISE DE CUSTO DE PAVIMENTOS PERMEÁVEIS EM BLOCO DE CONCRETO UTILIZANDO BIM (BUILDING INFORMATION MODELING). Revistaft, 26(111), 86. https://doi.org/10.5281/zenodo.10022486

Eliomar Gotardi Pessoa, Gabriel Seixas Pinto Azevedo Benittez, Nathalia Pizzol de Oliveira, & Vitor Borges Ferreira Leite. (2022). ANÁLISE COMPARATIVA ENTRE RESULTADOS EXPERIMENTAIS E TEÓRICOS DE UMA ESTACA COM CARGA HORIZONTAL APLICADA NO TOPO. Revistaft, 27(119), 67. https://doi.org/10.5281/zenodo.7626667

Eliomar Gotardi Pessoa, & Coautora: Glaucia Brandão Freitas. (2022). ANÁLISE COMPARATIVA ENTRE RESULTADOS TEÓRICOS DA DEFLEXÃO DE UMA LAJE PLANA COM CARGA DISTRIBUÍDA PELO MÉTODO DE EQUAÇÃO DE DIFERENCIAL DE LAGRANGE POR SÉRIE DE FOURIER DUPLA E MODELAGEM NUMÉRICA PELO SOFTWARE SAP2000. Revistaft, 26(111), 43. https://doi.org/10.5281/zenodo.10019943

Pessoa, E. G. (2025). Optimizing helical pile foundations: a comprehensive study on displaced soil volume and group behavior. Brazilian Journal of Development, 11(4), e79278. https://doi.org/10.34117/bjdv11n4-047