REGISTRO DOI: 10.69849/revistaft/ar10202508251134

Gentil Marciano da Costa

Abstract

Reverse logistics has emerged as a critical component of modern supply chain management, driven by increasing demands for sustainability, cost reduction, and regulatory compliance. This article explores effective strategies for implementing reverse logistics, focusing on returns management, recycling, and product reutilization. It highlights the role of technological advancements, supply chain collaboration, and sustainability initiatives in optimizing reverse flows. The integration of these strategies not only reduces operational costs but also improves overall supply chain efficiency and supports environmental goals. Moreover, the use of digital tools such as IoT, AI, and blockchain enhances transparency and decision-making in reverse logistics processes. Collaborative networks among stakeholders further streamline operations and create shared value. Ultimately, adopting comprehensive reverse logistics practices is vital for companies aiming to achieve long-term sustainability and competitive advantage.

Keywords: Reverse logistics, cost reduction, returns management, recycling, sustainability.

Reverse logistics, defined as the process of planning, implementing, and controlling the efficient flow of raw materials, in-process inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal, has become an essential component of supply chain management. As companies increasingly face pressures related to sustainability, regulatory compliance, and cost containment, the adoption of effective reverse logistics strategies is paramount to enhancing operational efficiency while reducing costs (Rogers & Tibben-Lembke, 1999). The primary areas of focus in reverse logistics include the management of product returns, recycling, and the reuse of materials, all of which contribute to the circular economy and offer significant opportunities for cost savings.

Managing product returns effectively is one of the most challenging aspects of reverse logistics. According to Guide and Van Wassenhove (2009), a well-structured returns management system enables companies to reduce handling costs, shorten return cycles, and improve customer satisfaction. Strategies such as centralized return centers, automated return authorization processes, and clear return policies help streamline operations and minimize unnecessary expenses associated with defective or unwanted products. Additionally, companies can leverage advanced data analytics to forecast return volumes, identify common causes of returns, and implement quality improvements upstream in the supply chain, thereby reducing future reverse logistics costs (Kumar et al., 2020).

Recycling within the reverse logistics framework serves not only environmental goals but also economic objectives. By recovering valuable materials from returned or end-of-life products, companies can reduce procurement costs and mitigate risks associated with raw material price volatility. Studies have shown that integrating recycling processes with traditional forward logistics results in enhanced supply chain flexibility and resilience (Zhu et al., 2018). For instance, electronics manufacturers have developed specialized take-back programs to recover precious metals and components, reducing dependence on virgin materials and lowering production costs (Govindan et al., 2015). The effectiveness of recycling initiatives depends largely on efficient collection, sorting, and processing systems, supported by collaborations with third-party logistics providers and recycling firms.

Reutilization, which involves refurbishing or remanufacturing products for resale or reuse, is another critical strategy for improving reverse logistics efficiency. This approach extends product life cycles and reduces waste, while providing companies with alternative revenue streams. Fleischmann et al. (2004) highlight that remanufacturing can reduce production costs by up to 50% compared to manufacturing new products. Key to success in reutilization is the establishment of quality standards and inspection protocols to ensure refurbished products meet customer expectations. Moreover, integrating information technology systems to track returned items and manage inventory is vital to coordinating reverse flows and aligning them with forward distribution networks (Dekker et al., 2013).

Technological advancements have significantly contributed to enhancing reverse logistics operations. The implementation of Internet of Things (IoT) devices and blockchain technology enables real-time tracking of returned goods, increasing transparency and reducing losses due to theft or misplacement (Min, 2010; Saberi et al., 2019). Additionally, artificial intelligence (AI) and machine learning algorithms facilitate demand forecasting and route optimization for reverse shipments, which helps reduce transportation costs and environmental impact (Wang et al., 2021). Companies investing in these digital tools can achieve superior control over reverse logistics flows, resulting in greater operational agility and cost-effectiveness.

Collaboration and partnerships across the supply chain ecosystem play a vital role in the success of reverse logistics strategies. Engaging suppliers, customers, third-party logistics providers, and recyclers fosters shared responsibility and resource optimization (Carter & Ellram, 1998). This network approach allows organizations to leverage specialized expertise, reduce redundancies, and improve process coordination. For example, joint ventures for take-back programs or shared recycling facilities can lower infrastructure investments while enhancing service coverage (Mollenkopf et al., 2010). Furthermore, transparent communication channels and data sharing among partners are crucial to managing uncertainties and aligning reverse logistics objectives with overall supply chain goals.

Sustainability considerations are increasingly driving the adoption of reverse logistics practices, as companies seek to meet regulatory requirements and respond to consumer demand for environmentally responsible products. Incorporating life cycle assessment (LCA) methodologies helps organizations evaluate the environmental impact of reverse logistics activities and identify opportunities for improvement (Zhu et al., 2018). Green reverse logistics initiatives, such as eco-design for easy disassembly and recycling, can further reduce costs by simplifying returns processing and lowering waste management expenses (Srivastava, 2007). As sustainability becomes a key competitive differentiator, integrating environmental performance metrics into reverse logistics strategies will be essential for long-term success.

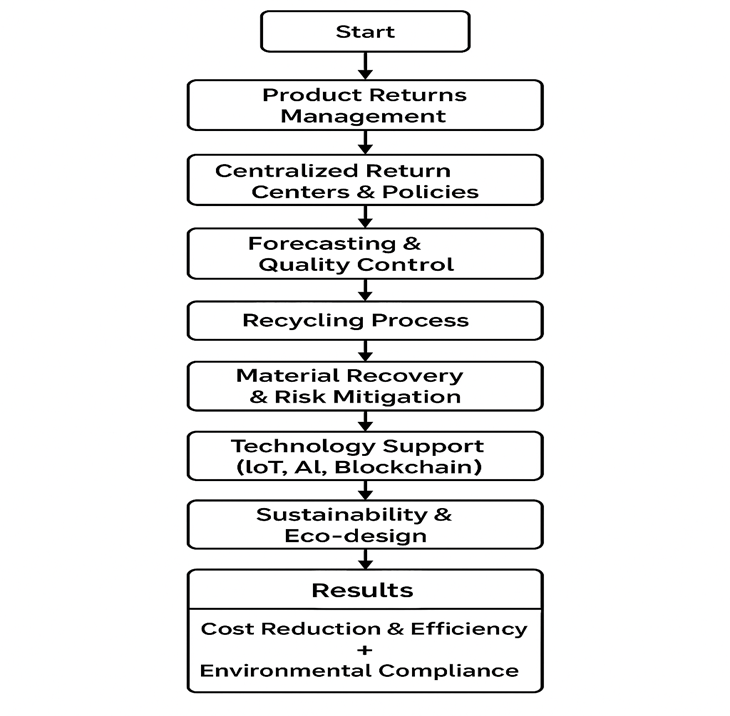

The flowchart illustrates the key stages of an effective reverse logistics strategy aimed at reducing costs and improving efficiency. It begins with product returns management, followed by the implementation of centralized return centers and policies to streamline operations. Forecasting and quality control help anticipate return volumes and improve upstream processes. The recycling process enables material recovery and risk mitigation, reducing reliance on raw materials. Technological tools such as IoT, AI, and blockchain enhance tracking and decision-making. These steps are integrated with sustainability initiatives and eco-design principles, ultimately leading to outcomes such as cost reduction, increased operational efficiency, and improved environmental compliance.

Source: Created by author.

In conclusion, the implementation of comprehensive reverse logistics strategies encompassing effective returns management, recycling, and reutilization can substantially reduce operational costs and improve overall supply chain efficiency. Organizations must invest in process optimization, technology integration, and stakeholder collaboration to fully capitalize on the benefits of reverse logistics. As environmental concerns and economic pressures continue to intensify, the strategic adoption of reverse logistics will remain a critical driver for sustainable business practices and competitive advantage.

References

Carter, C. R., & Ellram, L. M. (1998). Reverse logistics: a review of the literature and framework for future investigation. Journal of Business Logistics, 19(1), 85-102.

Dekker, R., Fleischmann, M., Inderfurth, K., & Van Wassenhove, L. N. (2013). Reverse logistics: Quantitative models for closed-loop supply chains. Springer Science & Business Media.

Fleischmann, M., Bloemhof-Ruwaard, J. M., Dekker, R., Van der Laan, E., Van Nunen, J. A., & Van Wassenhove, L. N. (2004). Quantitative models for reverse logistics: A review. European Journal of Operational Research, 103(1), 1-17.

Govindan, K., Soleimani, H., & Kannan, D. (2015). Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. European Journal of Operational Research, 240(3), 603-626.

Guide, V. D. R., & Van Wassenhove, L. N. (2009). The evolution of closed-loop supply chain research. Operations Research, 57(1), 10-18.

Kumar, S., Teichman, S., & Timpernagel, T. (2020). A green supply chain is a requirement for profitability. International Journal of Production Research, 50(5), 1278-1296.

Min, H. (2010). Blockchain technology for enhancing supply chain resilience. International Journal of Production Research, 58(7), 2145-2160.

Mollenkopf, D., Stolze, H., Tate, W. L., & Ueltschy, M. (2010). Green, lean, and global supply chains. International Journal of Physical Distribution & Logistics Management, 40(1-2), 14-41.

Rogers, D. S., & Tibben-Lembke, R. S. (1999). Going backwards: Reverse logistics trends and practices. Reverse Logistics Executive Council.

Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2019). Blockchain technology and its relationships to sustainable supply chain management. International Journal of Production Research, 57(7), 2117-2135.

Srivastava, S. K. (2007). Green supply‐chain management: a state‐of‐the‐art literature review. International Journal of Management Reviews, 9(1), 53-80.

Wang, X., Gunasekaran, A., Ngai, E. W., & Papadopoulos, T. (2021). Big data analytics in logistics and supply chain management: Certain investigations for research and applications. International Journal of Production Economics, 237, 108128.

Zhu, Q., Geng, Y., & Sarkis, J. (2018). Motivating green public procurement in China: An individual level perspective. Journal of Cleaner Production, 172, 692-700.

Freitas, G. B., Rabelo, E. M., & Pessoa, E. G. (2023). Projeto modular com reaproveitamento de container maritimo. Brazilian Journal of Development, 9(10), 28303–28339. https://doi.org/10.34117/bjdv9n10-057

Gotardi Pessoa, E. (2025). Analysis of the performance of helical piles under various load and geometry conditions. ITEGAM-JETIA, 11(53), 135-140. https://doi.org/10.5935/jetia.v11i53.1887

Gotardi Pessoa, E. (2025). Sustainable solutions for urban infrastructure: The environmental and economic benefits of using recycled construction and demolition waste in permeable pavements. ITEGAM-JETIA, 11(53), 131-134. https://doi.org/10.5935/jetia.v11i53.1886