REGISTRO DOI: 10.69849/revistaft/ma10202602101359

Sheila Silva de Melo

Abstract

The prevention of occupational accidents and environmental disasters is a fundamental challenge for organizations operating in environments characterized by complex processes and hazardous activities. Workplace accidents and environmental incidents can lead to severe human, environmental, and economic consequences, highlighting the need for proactive and integrated prevention strategies. This article examines key approaches to preventing accidents and environmental disasters in the workplace, emphasizing systematic hazard identification, risk assessment, integrated management systems, engineering controls, human factors, and emergency preparedness. By aligning occupational safety and environmental protection objectives, organizations can reduce the likelihood and severity of incidents while enhancing operational resilience and regulatory compliance. The analysis suggests that preventive strategies grounded in strong safety cultures and continuous improvement contribute significantly to sustainable organizational performance and long-term risk reduction.

Keywords: Accident Prevention; Environmental Disaster Prevention; Occupational Safety; Risk Management; Safety Culture; Environmental Protection.

The prevention of occupational accidents and environmental disasters is a critical challenge for organizations operating in sectors characterized by complex processes, hazardous materials, and high operational risks. Accidents such as explosions, chemical spills, fires, and uncontrolled emissions can result in severe human injuries, environmental degradation, and significant economic and reputational losses. Research in occupational safety and environmental management demonstrates that most workplace accidents and environmental disasters are not random events but are the result of identifiable and preventable failures in systems, processes, and organizational decision-making (Reason, 1997; Kletz, 2009).

Effective prevention strategies are grounded in systematic hazard identification and risk assessment. Organizations must continuously identify physical, chemical, biological, and organizational hazards and evaluate their potential consequences for both workers and the environment. Risk assessment tools such as hazard and operability studies, job safety analysis, and environmental impact assessments allow organizations to anticipate failure scenarios and implement preventive barriers before incidents occur. Studies in process safety emphasize that integrating environmental risks into occupational risk assessments significantly reduces the likelihood of large-scale accidents and environmental disasters (Khan, Amyotte, & DiMattia, 2009).

Management systems play a fundamental role in structuring accident and disaster prevention efforts. International standards such as ISO 45001 for occupational health and safety and ISO 14001 for environmental management provide systematic frameworks for identifying risks, implementing control measures, and promoting continuous improvement. Empirical evidence suggests that organizations adopting integrated management systems experience improved safety performance, enhanced regulatory compliance, and greater preparedness for emergency situations (Zeng, Shi, & Lou, 2007). These systems emphasize leadership commitment, worker participation, documentation, and performance monitoring, all of which are essential for effective prevention.

Engineering and technical controls represent another essential layer of accident and disaster prevention. The application of inherently safer design principles—such as minimizing hazardous inventories, substituting dangerous substances, and simplifying processes—reduces the probability and severity of accidents at their source (Kletz, 2009). From an environmental perspective, such measures reduce the risk of catastrophic releases and long-term ecological contamination. Studies show that preventive engineering solutions are more effective in reducing accident risks than reliance on administrative controls or personal protective equipment alone (Khan et al., 2009).

Human factors and organizational culture are equally critical in preventing accidents and environmental disasters. Many major incidents have been linked to human error, inadequate training, poor communication, and weak safety cultures rather than purely technical failures (Reason, 1997). Organizations that promote strong safety cultures—characterized by open communication, employee involvement, learning from near misses, and non-punitive reporting systems—tend to experience fewer accidents and better environmental performance. Training programs that enhance workers’ risk awareness and emergency response capabilities are particularly effective in reducing unsafe behaviors and improving preparedness for abnormal situations (Hopkins, 2012).

Emergency preparedness and response planning is a key component of comprehensive prevention strategies. Even in organizations with robust preventive systems, unexpected events may occur, making preparedness essential for minimizing harm. Emergency response plans, regular drills, and coordination with external emergency services improve an organization’s ability to control incidents and limit their environmental and human consequences. Research indicates that organizations with well-developed emergency management systems are more resilient and capable of preventing minor incidents from escalating into major environmental disasters (Khan et al., 2009).

The benefits of investing in accident and environmental disaster prevention extend beyond legal compliance. Preventive strategies reduce costs associated with injuries, environmental remediation, production interruptions, and legal liabilities. Moreover, organizations that demonstrate a strong commitment to prevention and environmental protection tend to enhance employee trust, public credibility, and long-term organizational sustainability (Hopkins, 2012). These benefits reinforce the view that prevention should be considered a strategic investment rather than an operational expense.

Despite the clear advantages, organizations often face challenges in implementing effective prevention strategies. Limited resources, insufficient technical expertise, and short-term economic pressures may undermine preventive efforts, particularly in small and medium-sized enterprises. Additionally, fragmented organizational structures and weak leadership commitment can reduce the effectiveness of management systems. Overcoming these barriers requires sustained leadership engagement, worker participation, and a long-term perspective on safety and environmental performance.

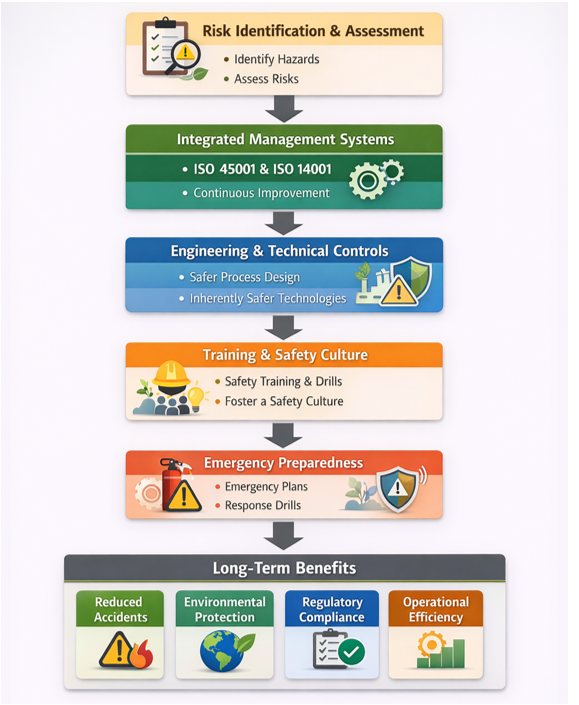

The flowchart presents a structured approach to preventing workplace accidents and environmental disasters by emphasizing proactive and integrated risk management. It begins with risk identification and assessment, where potential occupational and environmental hazards are systematically identified and evaluated. This stage feeds into integrated management systems, aligned with international standards such as ISO 45001 and ISO 14001, which support continuous improvement and coordinated safety and environmental controls. The process then advances to engineering and technical controls, focusing on safer process design and the adoption of inherently safer technologies to minimize the likelihood of failures. Training and the development of a strong safety culture play a central role by ensuring that employees are competent, aware of risks, and actively engaged in prevention efforts. Finally, emergency preparedness ensures that organizations are ready to respond effectively to incidents, reducing their potential consequences. Together, these steps lead to long-term benefits, including fewer accidents, enhanced environmental protection, improved regulatory compliance, and greater operational efficiency.

Figure 1. Prevention of Workplace Accidents and Environmental Disasters through Integrated Risk Management.

Source: Created by author.

In conclusion, the prevention of occupational accidents and environmental disasters requires an integrated and proactive approach that combines systematic risk assessment, management systems, engineering controls, human factors, and emergency preparedness. By embedding prevention into organizational culture and aligning occupational safety with environmental protection objectives, organizations can significantly reduce the likelihood and severity of accidents. As industrial activities continue to pose complex risks to workers and the environment, effective prevention strategies remain essential for achieving safe, resilient, and sustainable workplaces.

References

Hopkins, A. (2012). Disastrous decisions: The human and organisational causes of the Gulf of Mexico blowout. Sydney: CCH Australia.

International Organization for Standardization. (2015). ISO 14001: Environmental management systems – Requirements with guidance for use. Geneva: ISO.

International Organization for Standardization. (2018). ISO 45001: Occupational health and safety management systems – Requirements with guidance for use. Geneva: ISO.

Khan, F. I., Amyotte, P. R., & DiMattia, D. G. (2009). Process safety and environmental protection: Hazard identification and risk analysis. Oxford: Elsevier.

Kletz, T. (2009). What went wrong? Case histories of process plant disasters and how they could have been avoided (5th ed.). Oxford: Butterworth-Heinemann.

Reason, J. (1997). Managing the risks of organizational accidents. Aldershot: Ashgate.Zeng, S. X., Shi, J. J., & Lou, G. X. (2007). A synergetic model for implementing an integrated management system: An empirical study in China. Journal of Cleaner Production, 15(18), 1760–1767.